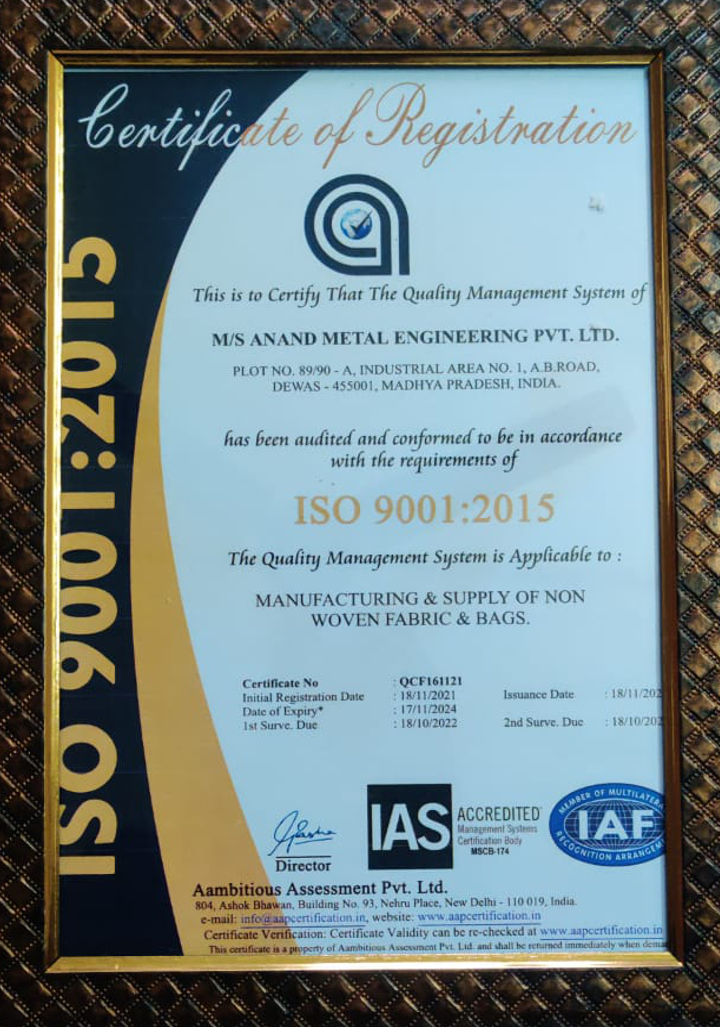

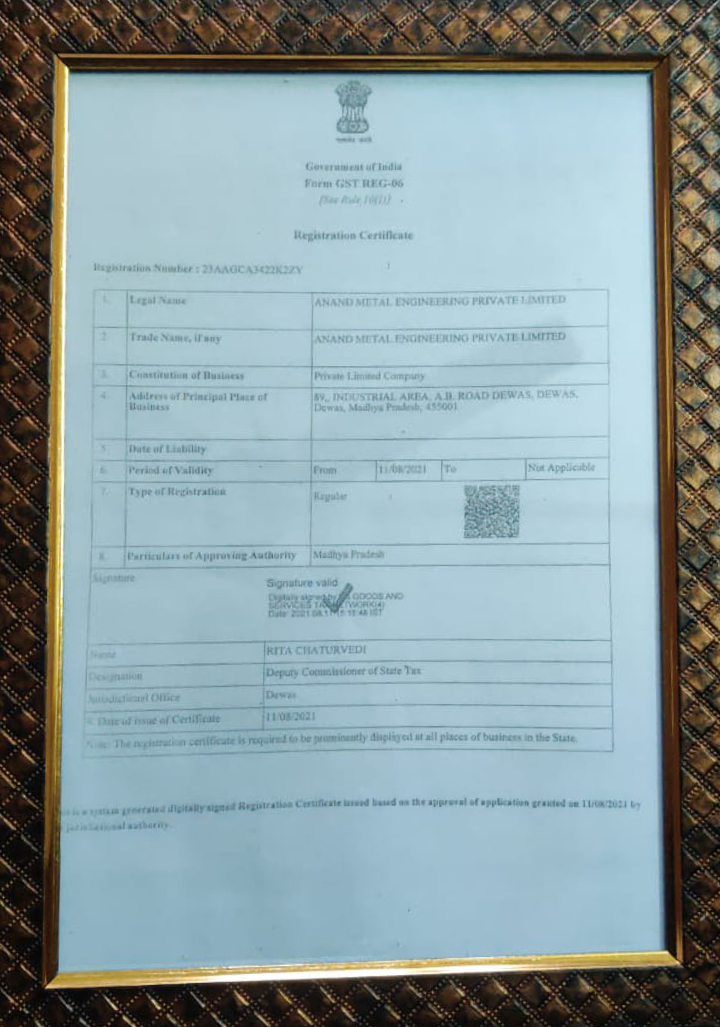

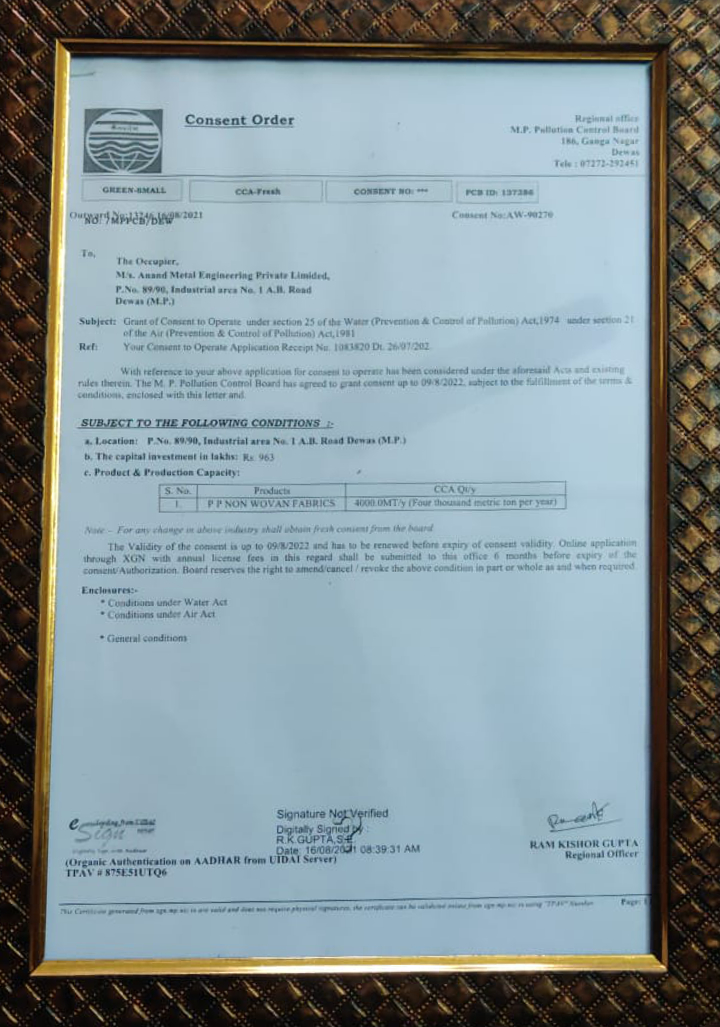

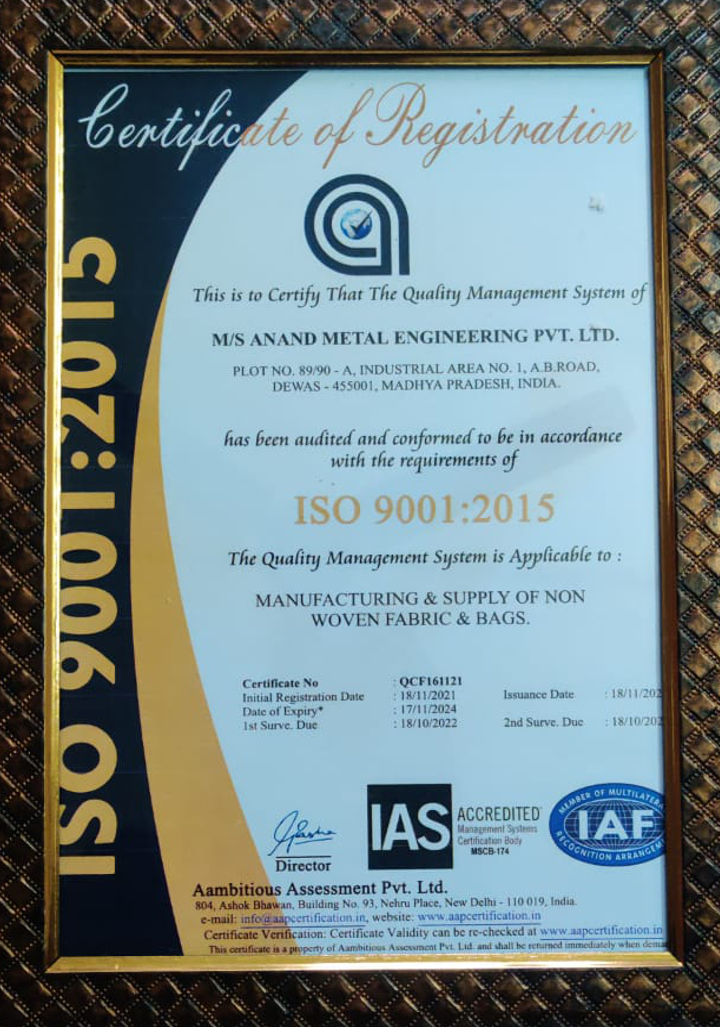

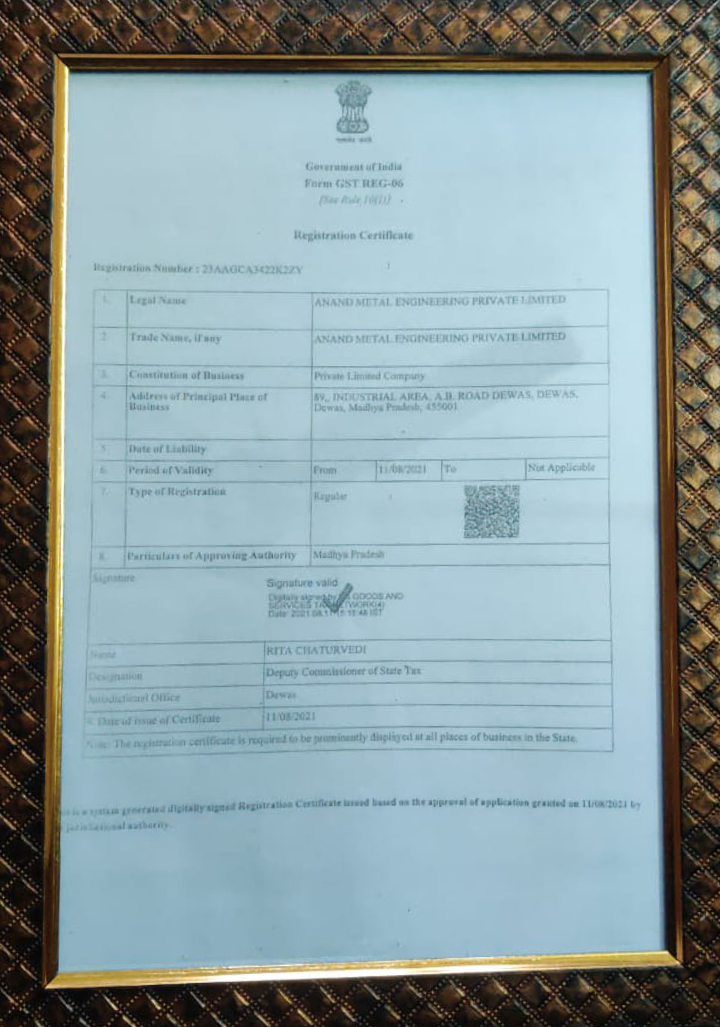

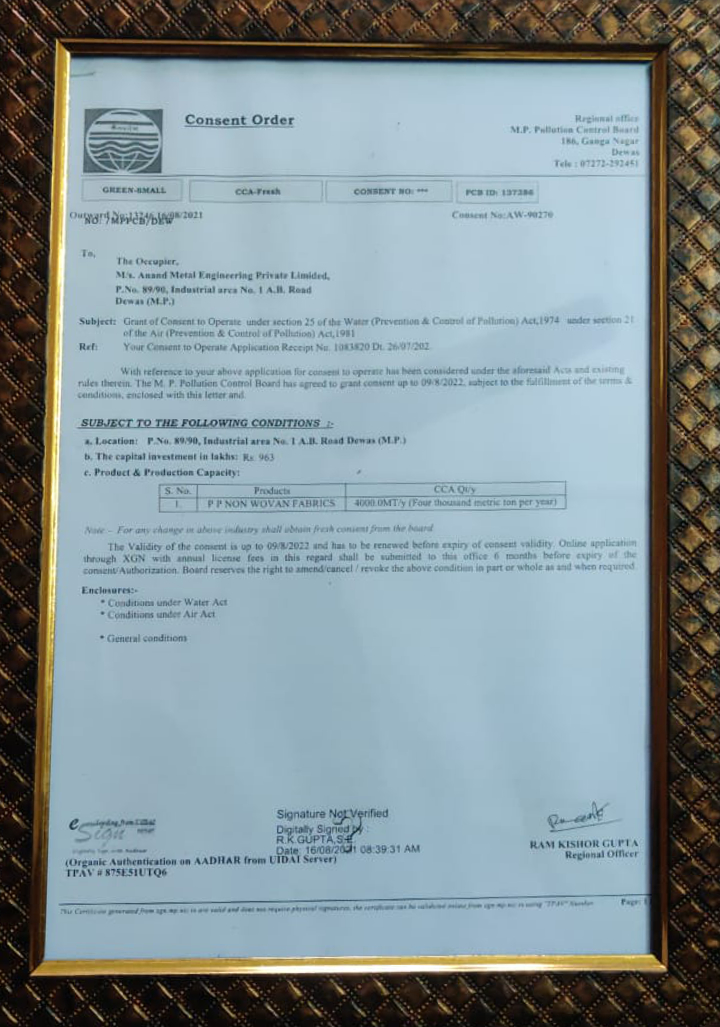

Our Certificates

At SV FABRICS, quality is more than a goal – it's our promise. Our commitment to delivering superior nonwoven fabrics is unwavering, ensuring our customers receive only the best. We adhere to the highest standards of quality and have implemented stringent quality control measures at every stage of the manufacturing process.

We follow a comprehensive quality policy that consists of rigorous testing and extensive inspections. Our laboratory is equipped to conduct a variety of tests, ensuring our products meet and exceed industry standards.

Purpose :Determines the amount of inorganic material in nonwoven fabric.

Procedure :A sample of the fabric is burned at a high temperature in a temperature controlled chamber. The residue left after combustion is weighed to calculate the ash content.

Importance : Ensures the purity of the fabric and evaluates the presence of any or contaminants that could affect the fabric's performance and quality.

Purpose :Measures the fabric's weight per unit area.

Procedure : A sample of the fabric is weighed and its area is measured to calculate GSM.

Importance : Ensures consistency in fabric thickness and density.

Purpose : Determines how much the fabric can stretch before breaking.

Procedure :The fabric is pulled to its breaking point, and the elongation percentage is recorded.

Importance : Assesses the flexibility and resilience of the fabric.

Purpose :Measures the fabric's resistance to breaking under tension.

Procedure : A sample is stretched until it breaks to determine its strength and durability.

Importance : Ensures the fabric can withstand significant stress without tearing.

Our quality control team conducts thorough inspections at every stage of production, from raw material selection to final product packaging. Here's how we minimize defects:

Regular visual inspections are performed to catch any issues the machines might miss.

Samples from each batch are rigorously tested to ensure they meet our quality standards.

Any defects detected are analyzed, and immediate corrective actions are implemented to prevent recurrence.

Quality is an ongoing journey at SV FABRICS. We are committed to continuous improvement, investing in the latest technologies and training our staff to stay ahead in the industry. By constantly evaluating and enhancing our processes, we ensure that our products remain at the forefront of quality and innovation.

“Premium non woven fabrics and shopping bags, proudly made in India. Discover quality and innovation in every product—experience the difference with us today!”

“SV FABRICS – Your Vision, Our Fabric”

© 2023-24 All Right Reserved by SV Fabrics

Crafted with ♥ by Cloud Zappy